Understanding the Role of an APU in Aviation

The Auxiliary Power Unit (APU) is an unsung hero in modern aviation. It’s the small gas turbine engine that powers essential aircraft systems when the main engines are not running. Whether on the ground or at 35,000 feet, the APU ensures critical systems like air conditioning, electrical power, and engine starts function seamlessly.

Every Boeing jet, from the narrow-body 737 to the wide-body 777, relies on this system. The operates independeAPUntly, providing both pneumatic (air pressure) and electrical power, enabling aircraft to remain self-sufficient without relying on ground power units.

What is an APU (Auxiliary Power Unit)?

An APU is essentially a small jet engine located in the tail cone of the aircraft. Its primary job is to:

-

Start the main engines using pneumatic air.

-

Provide electrical power to onboard systems.

-

Supply air conditioning during boarding and deboarding.

-

Serve as a backup power source during flight emergencies.

APUs in commercial aircraft usually run on Jet A-1 fuel and use a starter motor to begin rotation. Once operational, the APU powers a generator and an air compressor that supply power and air to the aircraft systems.

How the APU Works

The working principle of an APU is similar to that of a small gas turbine engine:

-

Air Intake: Ambient air enters through an intake duct in the tail section.

-

Compression: The air is compressed to high pressure.

-

Combustion: Fuel is injected and ignited, producing high-energy gases.

-

Turbine Rotation: The expanding gases drive the turbine, powering both the compressor and the generator.

-

Output: Electrical and pneumatic energy is supplied to aircraft systems.

Modern APUs, such as those in Boeing aircraft, are highly automated. Pilots can start or stop them using cockpit switches, with automatic fault detection and shutdown features.

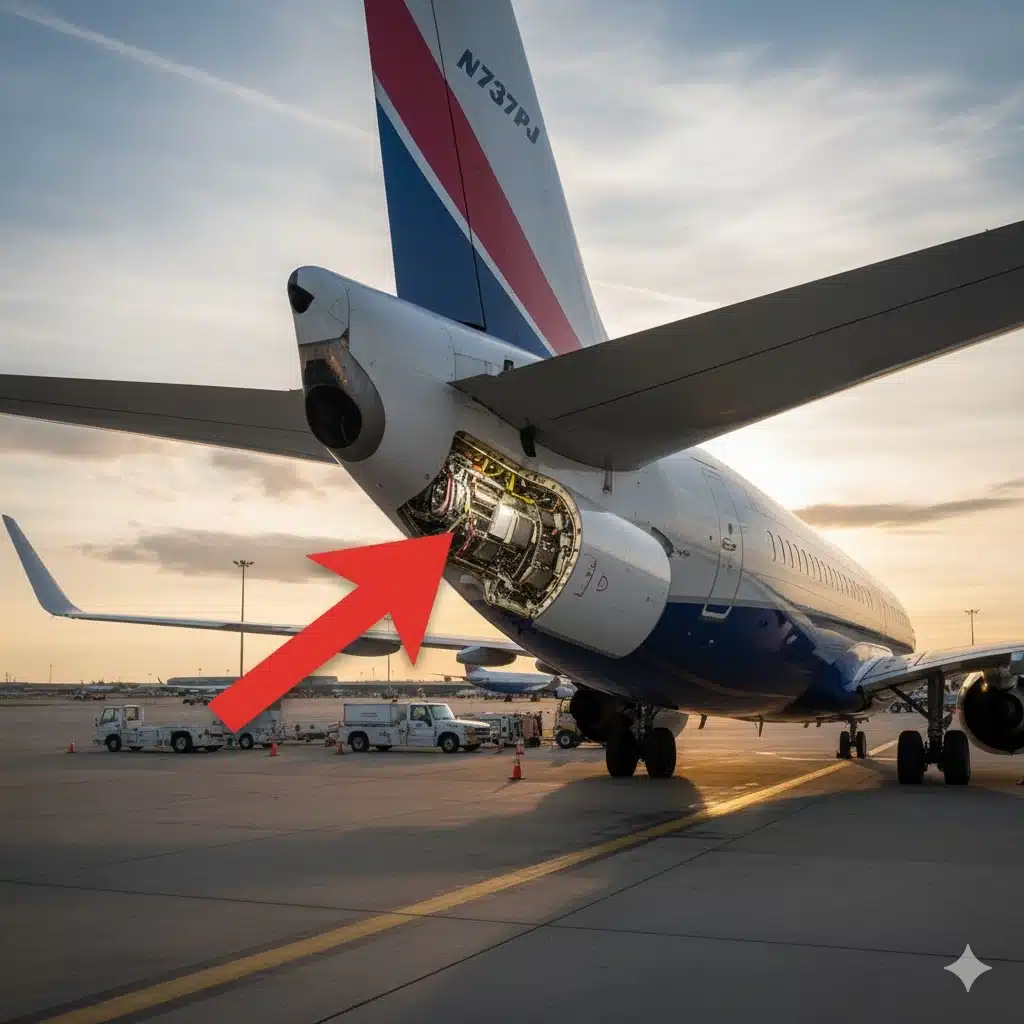

Boeing 737 APU Overview

The Boeing 737 series uses an APU manufactured by Honeywell Aerospace, primarily the GTCP131-9B model for the 737 Next Generation and MAX series. This APU is renowned for reliability, compact design, and fuel efficiency.

Technical Specifications of the Boeing 737 APU

| Specification | Description |

|---|---|

| Model | Honeywell GTCP131-9B |

| Weight | Approx. 175 kg |

| Power Output | ~90 kVA electrical, 40 psi pneumatic |

| Start Method | Electric starter motor |

| Fuel Type | Jet A / Jet A-1 |

| Mounting Location | Tail cone compartment |

This APU is capable of supplying enough air to start both main engines and maintain full electrical power for essential systems

APU Operation in Boeing 737

On the 737, the APU can be started using battery power or ground power. Once online, it automatically connects to the aircraft’s AC electrical system through the bus tie breaker. The APU bleed air is used for air conditioning and engine start.

During flight, the APU may be used as a standby generator, especially during single-engine operations or in the event of an in-flight engine shutdown.

Maintenance and Common Issues in 737 APUs

Routine maintenance includes:

-

Oil level checks.

-

Exhaust inspection for soot and leaks.

-

Performance monitoring during ground runs.

Common issues include starter motor wear, fuel control unit malfunction, and excessive vibration. Preventive maintenance extends operational life beyond 10,000 hours between overhauls.

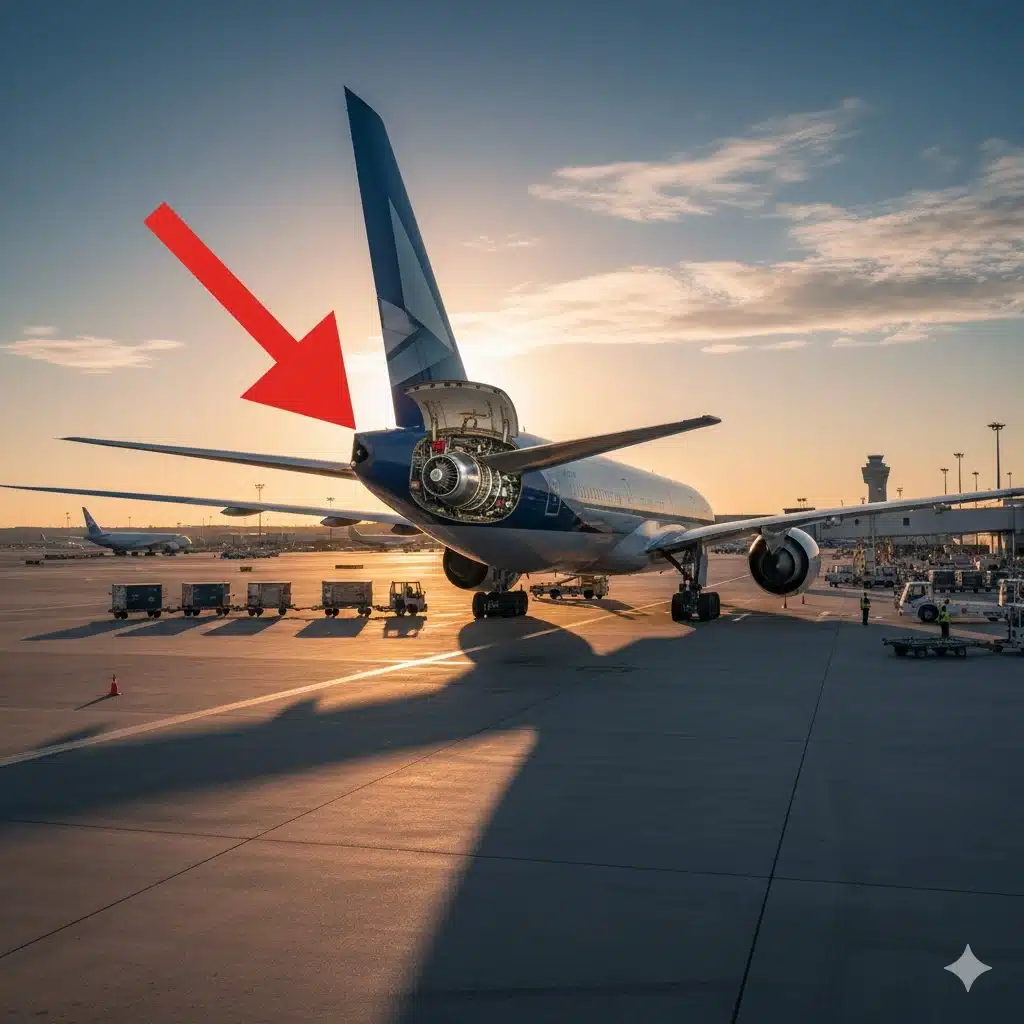

Boeing 777 APU Overview

The Boeing 777 employs a more powerful APU developed by Hamilton Sundstrand (now part of Collins Aerospace). The APU in this wide-body jet supports higher power demands due to its advanced avionics and multiple electrical systems

Technical Specifications of Boeing 777 APU

| Specification | Description |

|---|---|

| Model | Hamilton Sundstrand APS5000 |

| Weight | Approx. 240 kg |

| Power Output | ~120 kVA electrical, 50 psi pneumatic |

| Mounting Location | Aft fuselage, tail cone |

| Fuel Consumption | ~300 kg/hour (at full load) |

The APS5000 APU is known for high reliability and low emissions, meeting stringent international environmental standards.

Operation and Control of Boeing 777 APU

The APU in the 777 is fully integrated with the Airplane Information Management System (AIMS). Pilots control it via the Electronic Flight Bag (EFB) or overhead panel. Once started, it synchronizes automatically with onboard power systems, ensuring stable electrical and pneumatic flow.

During takeoff and climb, the APU can remain on standby, ready to support systems in case of an engine generator failure.

Maintenance Practices for Boeing 777 APU

Maintenance intervals are generally longer than in narrow-body aircraft, thanks to digital monitoring. Regular inspection tasks include:

-

Oil filter checks.

-

Vibration analysis.

-

Temperature and EGT trend monitoring.

Failures are rare but can include bleed valve sticking or fuel control unit issues. The 777’s APU features built-in diagnostics, simplifying troubleshooting for technicians.

Comparing Boeing 737 and Boeing 777 APU Systems

| Feature | Boeing 737 APU (GTCP131-9B) | Boeing 777 APU (APS5000) |

| Manufacturer | Honeywell Aerospace | Hamilton Sundstrand |

| Electrical Power | 90 kVA | 120 kVA |

| Pneumatic Output | 40 psi | 50 psi |

| Automation | Semi-automatic | Fully automated |

| Fuel Efficiency | Higher | Moderate |

| Maintenance Interval | 10,000 hours | 12,000 hours |

APU Safety, Redundancy, and Backup Systems

The auxiliary power unit (APU) is a critical subsystem in commercial aircraft, and its safety design, redundancy, and backup features are essential to ensuring reliable operations. Let’s explore how safety is built in.

Safety Features

-

Modern APUs include automatic shutdown capabilities: sensors monitor temperatures (EGT—exhaust gas temperature), vibration, oil pressure, and bleed-air pressure. If any parameter exceeds a threshold, the APU will shut down to protect the unit and the aircraft.

-

In the 777’s APU systems (e.g., APS5000 series), integration into the aircraft’s main monitoring/control system ensures that in-flight faults are fed to maintenance computers and cockpit alerts.

-

Fire detection and suppression: Tail-mounted APUs are equipped with fire-detection loops and fire-extinguishers (often halon or newer agents), similar to engine fire-zones.

-

Redundant power path: While the APU can supply electrical and pneumatic power, aircraft like the Boeing 777 typically have multiple main engine driven generators, RAT (ram-air turbine) or emergency batteries, so that APU failure doesn’t lead to total loss of power.

Redundancy & Backup

-

On the Boeing 737, the APU provides an independent secondary source of electrical/pneumatic power when main engines are off. In flight, if a generator from a main engine fails, the APU can be used (depending on altitude/air-bleed condition) to supply required power or bleed air.

-

The design philosophy is: “fail safe”. APU failure should not jeopardize safe flight. Thus the main engine systems are designed first, with the APU as support.

-

Many operators schedule the APU to remain on during taxi, take-off, or early climb until electrical/bleed load is transferred to the main engines, reducing risk of single-point failure.

-

Maintenance programs include built-in life-limits for rotating components, life-limited parts (LLPs) and inspection thresholds to detect fatigue or wear early.

Case Studies & Lessons

-

There have been incidents in which APU bleed-air contamination caused air-quality events in cabins (for other aircraft types) — leading manufacturers to refine seal-designs and inspection intervals.

-

For wide-body aircraft such as the 777, the APU is part of the airplane’s ETOPS (Extended Twin-Engine Operations) plan backup: if both main engines fail, the APU may serve as one of the backup power/bleed sources.

-

Regular engine cycles and thermal cycling of the APU demands that its maintenance program include vibration monitoring, compressor/turbine clearances, and oil system inspections.

In summary: The APU is designed with high reliability, fault detection, redundancy and backup support to ensure that the aircraft remains safe even if that unit fails. Maintenance regimes reflect that criticality.

The Evolution of APU Technology in Boeing Aircraft

APU technology has evolved considerably since its introduction, and understanding that helps explain why the systems on the Boeing 737 and Boeing 777 differ so markedly.

Early APU Designs

-

In earlier commercial jets the APU was less automated, heavier, and less fuel-efficient. It was primarily used on the ground for cabin environmental control and engine starting.

-

As aircraft systems became more electrically and pneumatically demanding, APUs grew in size, output and complexity.

Modern Digital Control & Efficiency

-

The Honeywell GTCP131-9 series (used in 737 NG/MAX) and the Hamilton Sundstrand (now Collins Aerospace) APS5000 (used in the 777) are examples of modern APUs with full digital FADEC-style control, sophisticated start sequences, automatic fault logging, and optimized fuel consumption.

-

The modern units also have lower emissions and improved noise-muffling compared to older units, to meet stricter environmental and airport noise requirements.

Integration with Aircraft Systems

-

With the Boeing 777, APU operation is integrated with the aircraft’s onboard management system (such as the Airplane Information Management System), so starting, monitoring and shutdown are automated for crew convenience.

-

The Boeing 737’s systems are somewhat simpler but still incorporate automatic bleed-air transfer, generator synchronization and automatic cooling/ventilation of the APU compartment.

Materials and Design Improvements

-

Use of advanced alloys, improved bearings, better sealing and cooler-running compressors have extended life-cycles, reduced maintenance intervals, and increased reliability.

-

Thermal- and vibration-resistant designs address the high-stressing environment in the tail cone where APUs operate.

-

Enhanced accessibility and modularity of parts make removals/overhauls faster, reducing APU downtime (which is important for airlines).

Thus over time, the APU has gone from a simple “ground‐aid” to a highly capable, integrated aircraft system supporting both ground and flight operations. This evolution explains why the 777’s APU system is more advanced (and expensive) than the 737’s.

Environmental and Regulatory Compliance

APUs must adhere to increasingly strict regulations covering emissions, noise, fuel efficiency and safety. Here’s how that shapes their design and operation.

Emissions & Fuel Efficiency

-

APUs burn Jet A1 fuel and produce CO₂, NOₓ, unburned hydrocarbons, and particulates. Regulators such as the ICAO (International Civil Aviation Organization) set emission standards for both engines and auxiliary power units.

-

Manufacturers design APUs to operate at high efficieny and meet certification standards for emissions (often required for noise‐sensitive airports).

-

Airlines monitor APU runtime, optimizing usage (for example using ground power units (GPUs) when possible) to reduce fuel burn and emissions on the ground.

Noise Control

-

Many airports impose noise restrictions during night operations. Tail‐mounted APUs have noise mufflers and intake/exhaust silencer systems to reduce footprint.

-

Airlines operating in noise‐sensitive regions (e.g., European city airports) may minimize APU usage during boarding or de-boarding where possible.

Certification & Maintenance Oversight

-

APUs are certified components and must meet airworthiness standards (FAA in the U.S., EASA in Europe, CAAC in China, etc.). Overhaul facilities must hold repair station approvals (e.g., FAA Part 145, EASA Part 145) for the region.

-

Regulatory bodies require periodic inspections (e.g., scheduled shop visit every certain hours, cycles) and oversight of life-limited parts. Operators must track parts and maintenance via documentation (“logbook”) to maintain APU airworthiness.

-

Contractual maintenance programs (engineers and MROs) often include compliance with relevant service bulletins, ADs (Airworthiness Directives) and OEM upgrade programmes (e.g., seal upgrades, compressor blade modifications) to maintain reliability and certification.

Sustainable Aviation Trends

-

With increasing attention to sustainability, airlines and manufacturers are exploring electric APUs or battery‐assisted systems that reduce fuel usage and emissions while on the ground.

-

Some airports and manufacturers also look at APU timers or automatic shutdown logic to limit unnecessary runtime and thus carbon footprint.

Hence, regulatory and environmental demands play a major role in APU design, maintenance and usage policies for airlines operating Boeing 737 and Boeing 777 fleets.

Future of APU Technology in Commercial Aviation

Looking ahead, APUs are likely to evolve further. Several trends are worth noting.

Hybrid & Electric APUs

-

Some manufacturers are exploring purely electric auxiliary systems or battery-based ground power units that could reduce or even eliminate traditional turbine APUs for certain operations (e.g., at gate).

-

Hybrid systems may use a small gas-turbine plus electric motor to start, reducing fuel consumption and noise.

Lower Emissions & Sustainable Fuels

-

Future APUs may be designed to operate on SAF (Sustainable Aviation Fuel) or bio-fuels to reduce carbon footprint.

-

Incorporation of advanced control algorithms for start/stop sequencing, optimized bleed-air distribution and reduced idle fuel burn.

Digitalisation & Predictive Maintenance

-

The next generation of APUs will increasingly leverage IoT sensors, condition monitoring, vibration analytics, and predictive maintenance to anticipate faults rather than reactive overhaul.

-

Airlines may subscribe to “APU as a service” contracts – paying hourly usage fees rather than owning the unit, while the OEM/MRO handles monitoring and overhaul. This model is already in use for engines and may extend to APUs.

Integration with Hybrid Aircraft and New Platforms

-

With electric/hybrid aircraft concepts emerging, APUs may become even more critical for managing alternative power systems, onboard energy storage, and standby operations.

-

For long-haul aircraft (such as the Boeing 777 successor or future jets), APUs may incorporate more advanced “multi-function” units serving both bleed-air, electrical and environmental control functions, reducing the number of separate systems onboard.

In essence, the APU’s role may expand beyond just auxiliary power — becoming a more integral energy management hub within the aircraft. Airlines and MROs alike are preparing for this shift.

Third-Party Manufacturers, Suppliers and MRO Companies – Region-Wise

An important dimension of APU support is the global network of manufacturers, parts-suppliers and MRO facilities. Here’s a breakdown by region for the Boeing 737 and Boeing 777 APU systems.

Manufacturers & OEM Suppliers

-

Honeywell Aerospace: Manufactures the GTCP 131-series APUs used on Boeing 737. It is also the OEM for GTCP331-500 series used on many wide-bodies including early 777s.

-

Hamilton Sundstrand (now part of Collins Aerospace): Developed the APS5000 series APU used on Boeing 777.

-

Parts suppliers (turbine/compressor blades, bearings, seals, fuel-control units) are often aftermarket vendors certified by OEMs, but the main OEM remains Honeywell or Collins depending on model.

MRO and Parts Support – Region: Asia

-

SIA Engineering Company (Singapore): Provides line maintenance, heavy checks and component overhaul for aircraft in the Asia-Pacific region. While not exclusively APU specialists, they form part of the regional support chain. Wikipedia

-

India: Air Works (Gurgaon, India) – independent MRO with expanding capabilities, which could service component/airframe but not always APU-specific; good regional resource. Wikipedia

-

China: Many Chinese MROs (e.g., those approved by CAAC) provide component maintenance; for APUs, airline-specific contracts often exist.

-

Example specific to APUs: Russian operator Yakutia Airlines (for Boeing 737) used Turkish provider for GTCP131-9B APUs. rusaviainsider.com

MRO and Parts Support – Region: Europe

-

EPCOR B.V. (Netherlands): A centre of excellence for APU and pneumatic components. APU repair & overhaul capable of GTCP131-9 series and GTCP331-500 units. Aviation Pros+1

-

Turkish Technic (Turkey): Authorized service centre for Honeywell GTCP131-9A/B APUs and other components for Boeing 737/737MAX. Times Aerospace+1

-

Many large European carriers/governments rely on such independent MROs to service APUs for Boeing fleets across Europe, Middle East & Africa.

MRO and Parts Support – Region: Middle East / Africa

-

Saudia Technic (Saudi Arabia): Under contract with Honeywell; first sole authorised service centre in the Middle East for GTCP331-500 APU installed on Boeing 777 in the region. aerospace.honeywell.com+1

-

Saudia Aerospace Engineering Industries (SAEI): Provides MRO for Honeywell APUs including GTCP331-500 and GTCP331-350 in Middle East. AGN

MRO and Parts Support – Region: Russia / CIS

-

Russian airlines, such as Yakutia Airlines, send their Boeing 737 APU units (GTCP131-9B) to Turkish Technic in Turkey (which holds the certification) due to lack of local certified APU overhaul capability in Russia. rusaviainsider.com

-

Operators may face increased logistical cost and downtime due to cross-border component shipping, export controls and certification issues.

Global MRO & Contract Examples

-

TAT Technologies Ltd. (USA/Israel) is a global APU MRO provider. They are Honeywell-certified for GTCP 131-9A/9B (Boeing 737) and GTCP 331-500 (Boeing 777) platforms. tat-technologies.com+2Stock Titan+2

-

Contract: TAT secured a 5-year global APU support contract valued US$40-55 million covering Boeing 737/777 and Airbus types. PR Newswire+1

-

Example: In Europe, EPCOR’s contract renewal with Kuwait Airways for Boeing 777 APUs (GTCP331-500) is a three-year agreement via EPCOR’s facility in the Netherlands. Aviation Week Network+1

Parts Supply Chains and Considerations

-

Airlines often rely on OEM or certified parts-suppliers for life-limited items (roller bearings, seals, combustor liners, compressor/turbine blades) to maintain the APU within airworthy condition.

-

Airlines/lessors often maintain a pool of spare APUs (particularly for high-utilisation fleets like 737s) so that a removed unit can be swapped and sent to the MRO centre while the aircraft returns to service. Example: Biman Bangladesh Airlines tender for repair/overhaul of GTCP131-9B and noting they will maintain a spare APU. biman.gov.bd

-

Logistics, export/import controls, certification (FAA/EASA/CAAC) of parts for APUs play a major role. Airlines often choose MRO centres close to their base to reduce logistics and downtime.

Putting It All Together – Operational Best Practices for Airlines

For an airline operating Boeing 737s and Boeing 777s, here are some practical best-practices regarding APU management:

-

Maintain a spare APU (or pool-unit) for fast turnaround. Having the aircraft down waiting for APU shop visit is costly.

-

Select an MRO partner with OEM certification for your APU model (GTCP131-9B for 737; GTCP331-500 or APS5000 for 777) and monitor their turnaround time, quality metrics, and cost.

-

Create a maintenance-interval tracking system for the APU: note hours operated, start-cycles, bleed-air output, vibration/temperature trends, oil consumption.

-

Optimize ground usage: Whenever feasible, use GPUs or ground air rather than running the APU long-term, especially in noise/emission‐sensitive airports.

-

Build in predictive monitoring: Leverage sensor data on EGT, vibration, oil‐system health to schedule proactive swaps before failure.

-

Coordinate with the MRO & parts-supplier network: Know which regional facility (Asia, Europe, Middle East, Russia/CIS) you plan to use for overhaul/repair, and consider logistics, lead-time, spare unit availability and cost.

-

Stay current with all OEM service bulletins/ADs for your APU model and implement required upgrades (e.g., seal improvements, compressor modifications) to stay compliant and reliable.

-

Align APU policies with environmental regulations: For example, ensure your APU runtime at gate complies with airport noise curfews, and evaluate fuel-burn cost vs GPU usage.

FAQs About Boeing 737 & Boeing 777 APU Systems

Q1: What is the difference between the APU used on Boeing 737 and Boeing 777?

A1: The Boeing 737 commonly uses the Honeywell GTCP131-9 series APU (or variants) which is optimized for narrow‐body operations: lower output, lighter weight, simpler systems. The Boeing 777 uses a more powerful units such as the GTCP331-500 or APS5000 APU, designed for high-demand wide‐body operations – higher electrical/pneumatic output, heavier and more complex.

Q2: How often does an APU need overhaul on a Boeing 737 or Boeing 777?

A2: Overhaul intervals vary by usage (hours, starts, bleed cycles) and operator policy. As a rule of thumb, an APU may undergo a shop visit every several thousand hours or after a certain number of cycles (often tens of thousands of starts for smaller APUs). The exact interval is determined by OEM recommendations and operational profile.

Q3: Can an airline replace the APU with a newer design after the aircraft is delivered?

A3: Yes — airlines can incorporate upgrade kits for APUs (e.g., improved seals, compressor stages) or even replace an APU with a later approved variant if certified. However this involves engineering changes, certification/approval by regulatory authorities, and logistics/time costs.

Q4: What happens if the APU fails in flight on a Boeing 777?

A4: If the APU fails in flight, it generally does not compromise safe flight because the aircraft’s main engines supply primary power/bleed. The APU serves as a backup or is used in ground/early climb phases. The failure will, however, trigger the aircraft’s maintenance reporting and may require landing as soon as practical for repair.

Q5: Are there regional challenges in servicing APUs for Boeing aircraft?

A5: Yes — depending on region, availability of certified MRO facilities, logistic lead-time, parts supply, certification approvals (FAA/EASA/CAAC) and export controls can affect APU overhaul. For example, in CIS/Russia some operators send units abroad because local capability is limited. rusaviainsider.com

Q6: How can an airline reduce APU operational costs?

A6: Several strategies: limit APU runtime on ground by using ground power units (GPUs) or pre-cooling; maintain a spare unit to reduce aircraft downtime; choose MRO centres with strong performance/turnaround; schedule proactive maintenance via condition monitoring; negotiate pool/spare contract with the OEM or MRO partner.

Conclusion

The APU systems on the Boeing 737 and Boeing 777 are more than just auxiliary helpers — they are essential power and bleed‐air sources that support everything from engine starts to cabin cooling, and in some cases safety backups. Understanding the differences between the APU platforms — GTCP131-9 series on 737s and GTCP331-500/APS5000 on 777s — helps airlines optimise operation, maintenance and lifecycle cost.

From the evolution of APU technology to its integration with modern aircraft systems, from safety and redundancy design to environmental and regulatory compliance, the role of the APU continues to grow. Pairing that with a global network of certified MROs and parts-suppliers (covering Asia, Europe, Middle East, Russia/CIS) is vital for ensuring high reliability, minimal downtime and cost efficiency.

For any airline operating these aircraft types, a well-planned APU maintenance strategy — including selection of the right MRO partner, managing spares, implementing condition monitoring, aligning with environmental policies, and staying current with OEM upgrades — will translate into better fleet performance and lower operational risk.